There is a lot of talk in the business press regarding innovation and how critical it is to western countries, keeping our lead in the world economy. Growth is driven by innovation and I thought it would be worth having a look at innovation in the context of motorsports. Below is a classic graphic showing the three phases of innovation: product, process and strategic.

Where is F1 currently?

I hypothesize that F1 is in the final stages of the process innovation: hopefully to be followed by the strategic innovation stage, most likely driven by the economic crisis and the withdrawal of many of the automotive giants that have driven the process innovation that has characterised the last 10-15 years.

So which era of Formula One characterised the product innovation stage?

First it is worth noting what drivers performance in motor racing. First order drivers of performance come from the areas that most closely effect the basic laws of physics such as Newtons laws of motion.

Initially innovation focussed on engines. Enzo Ferrari was one of the people who focussed most on engines and throughout his leadership of the company this is where the focus remained. It wasn’t until the 60’s when vehicle dynamics started to become seen as important with the move towards rearward engines. Without performing a large analysis on the subject his is most likely because of the changing engine efficiencies: smaller more efficient engines meant that they were no longer the dominant part of the vehicle from a weight and size point of view.

The fact that aerodynamics and tyres required much more complex methods of understanding meant that they came a lot later in the innovation cycle. Aerodynamics was the next area that began to show promise with the introduction of wings. This brought with it a huge boom in innovation. Wings sprouted allover the place. To take this to extremes Gordan Murray even introduced a fan car that was created downforce directly proportional to the fan! Most innovations were banned or controlled but innovation keep moving on.

Perhaps the next big area of innovation was active suspension. This innovation came when engineers realized that the car was also just one big wing with floors running so close to the ground they had become venturis. This innovation continued for a while but again it had to be controlled as the performance coming from these innovations was spiraling out of control!

Motor Manufacturers

Then came the motor manufacturers. I mean the big ones, not Ferrari, which has always been what I would call a stand alone sports car manufacturer, even though is owned by Fiat. I think Fiat simply provides stability.

The motor manufacturers I am talking about are the bigs ones: Honda, Toyota, Renault, Mercedes Benz, Ford and BMW. Only one remains when this blog was posted: Mercedes Benz. Their entry into the sport really started at the end of the 90’s when Ford began to take over Stewart Grand Prix. Renault followed in 2000, Honda took over Tyrell, Mercedes started investing in McLaren, Toyota started from scratch and BMW began to try to work closer with Williams.

The car companies did a few things, one of which was to bring more rigor to F1: just look at how reliability increased over the last 10 years. I recently presented to a conference on carbon composites and showed a simple explanation of what happened when rigor is introduced into a sport.

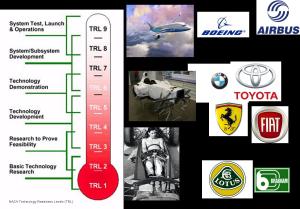

I found that NASA’s Technology Readiness Levels (TRL) were the best way of describing the changes that had happened in Formula One. The technology readiness levels are supposed to be used to describe new innovations and their stage in development: everything from Blue Sky research to developments that are fully ready for integration into mainstream commercial activities.

The slide was used to compare motor racing to aerospace and most of the explanation came down to the differences in risk taking. This got me thinking about what effect the motor manufacturers (OEM’s) have had on the sport and I decided that part of it was the rigor that aerospace and OEM’s need for selling products. This got me thinking about process innovation as this rigor is mostly about better quality, more certainty and less risk. So the TRL graphic highlighted this fact, especially when compared to the old days of Lotus and Brabham! In F1 history, many of the engineers would come up with concepts at the track and they would be on the car in a matter of hours! This was real Blue Sky territory, albeit at the expense of rigor, which I believe then brought reliability.

Part 2: Process innovation. Coming soon…